Tension Leveling

Overview of Tension Leveling:

The tension roller device is a kind of equipment used to implement tension regulation on the continuous production line of strips. The principle is as follows: the strip steel is winded on the tension roller and generates friction on the winding contact, making the outlet tension and inlet tension change according to some rules for this reason, and the tension value is thus changed to implement tension control of the unit.

The tension roller unit is used to make the torque acted on it by driving device transform to strip tension through the friction between the roller face and the strip, the quantity and layout form of the tension rollers depends on the maximum tensile strength and site conditions required by strips.

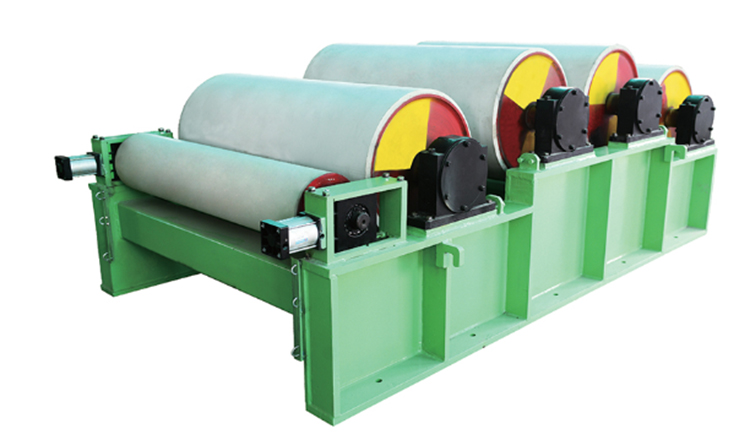

Tension Roller of Tension Leveling:

Diameter: 400-1200mm;

Press roller: 1-4 press rollers can be selected, diameter of 200-350; driven by air cylinder or hydraulic cylinder;

Matching devices: servo or dedicated variable-frequency AC motor