Inlet(outlet)loopers of metal color coating line manufacturer

Overview:

During normal production, the looper operates at set tension, so as to guarantee the balance of the unit tension and guarantee certain capacity. The speed of the inlet section basically maintains consistent with that of the process section. When replacing the coil at the inlet and outlet sections, in order to guarantee the unit of the process section operates normally at designed speed, the loop at this time is responsible for the discharge and feeding and guarantees the set tension to make the steel strip of the process section still operate continuously and steadily, After completing coil replacement, when the unit operates again, the looper will automatically maintain the original capacity.

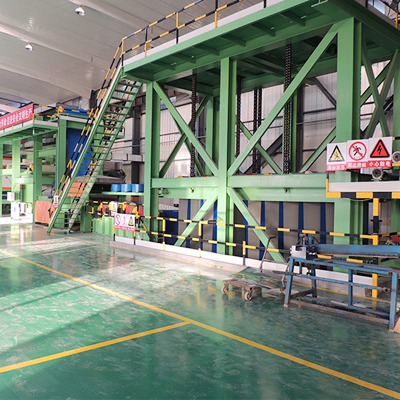

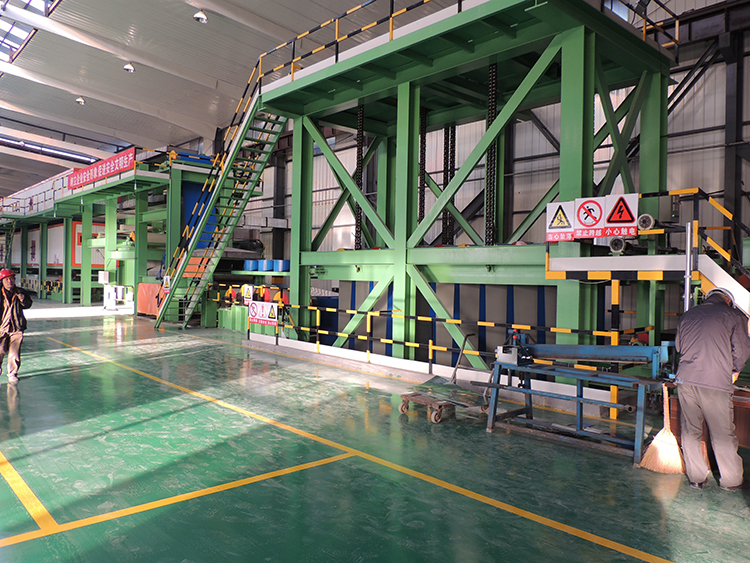

Composition and Structure:

The looper includes one trolley moving vertically, and is composed of roller system, winding plant, balance weight, rail and tower steel frame etc.. When charging and discharging the looper, the winding of trolley will pull the trolley to operate up and down, and the encoder on the looper motor records the position of the looper. The looper can also increase the deviation-correcting units as required to guarantee the strip steel not to deviate during the operation process.

Control System:

The inlet(outlet) looper control system is mainly composed of computer monitoring system, PLC process control system and drive control system. PLC control system is composed of SIEMENS S7-300 series of programmable controller, and communicates directly with the drive control system by means of profibus-DP communication. PLC program processes the speed control and tension control. The control mode and tension parameters of looper are operated by operators on the operation desk and operation control screen. The computer monitoring screen displays the charging and discharging speed of looper, the storage capacity of looper and the tension of looper etc.. Control of inlet(outlet)loopers mainly includes position control, synchronous control , speed control and tension control.