GEIT Electric Equipment Factory

Furnace-color coating line

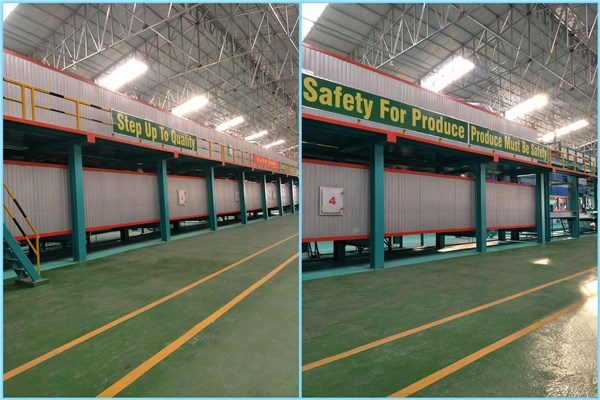

The furnace in color coating line is also usually called oven, we have talk a lot about this in the chapter of coating room-color coating line. you can click the link for a reference.

The two oven in color coating line are both of pendent type, it adopts mulit-layer labyrinth flashboard structure having good themal insulation effect. the primer oven and finish oven are set with different temperature control sections along their length separately, and equipped with multiple sets of hot air circulating device, waste gas collection and decomposition treatment, automatic temperature control etc. The curing time of steel strip in the oven is determined by strip thickness, coating type, coating thickness and curing temperature. the temperature in oven is different, the maximum surface temperature(PMT) of metal is different. and the oven temperature and its distribution are determined by the parameters of strip thickness, coating type, coating thickness and unit operate speed.

Besides, the catalytic incineration system is also important thermal part in color coating line. the incinerator is made of steel. it is used to empty the incinerated waste gas and apply the heat released to the centralized heating.

- The incinerators are insulated by fibrous materials, allowing them to warm up or change temperature more rapidly and reducing the substantial losses of the heat contained in the walls during long shutdowns.

- The use of separate final incinerator to treat the gases discharged into the atmosphere makes the oven independent of pollution problems.

- Secondary energy recovery takes place after this final incinerator and its operation does not affect that of the oven.

- To keep its consumption to a minimum, the flow of the exhaust blower is adjusted to match the exhaust temperature.

The Last step: Coating room – Color coating line

The next step: Exit looper – Color coating line