GEIT Electric Equipment Factory

Entry Looper – Color coating line

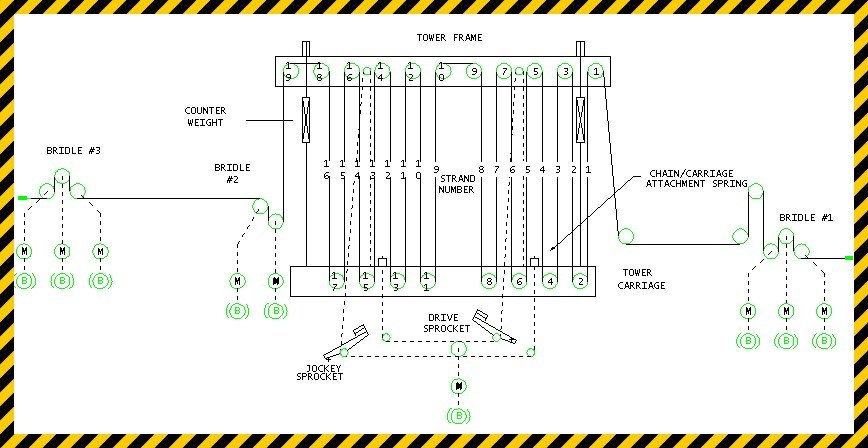

The Entry looper is also called strip accumulator/Inlet looper/entry tower, it allows the steel (aluminium) strip to be carried out without stopping the process line. It widely used at continuous color coating line, galvanizing line, cold rolled annealing pickling line etc. It consists of a cart, roller system, winding device, balance weight, rail and tower steel frame etc.. and it can also add the deviation-correction system to guarantee the strips forward parallelly during the operation.

The entry section is to the right of the entry tower and the process section is to the left. When the entry section speed matches that of the process section speed the tower carriage is down and the entry tower is full. During coil changes the entry tower empties, allowing the process section to continue uninterrupted.

Figure 1

The entry looper is mainly controlled by tension control and speed control. The entry tower tension zone is between bridle #1 and bridle #2. Bridle #1 is the lead entry section and it determines the speed of new strip enters the entry looper zone. When the entry and process section speeds are equal, entry looper carriage position is maintained by a proportional only position loop closed around bridle #1. During an entry section coil change, the proportional only position regulator is disabled and the entry section follows a ramped speed reference to a stop.

The entry looper carriage motor is rated for stall torque operation and provides strip tension in the entry tower tension zone. It has two type of operation while the line is running, they are current and tension. Current mode operation provides strip tension by regulating armature current. and the tension mode uses a tension meter located on tower roll #12 as feedback to a tension regulator.

The rate at which strip exits the entry looper is ultimately determined by the temper mill, which is the lead process section. Seven tension zones employing 56 separate motors and static drives transport the strip from the entry tower to the temper mill. The strip is heated and coated in this region, changing the physical and metallurgical properties of the strip. In order to keep the complexity of the system model reasonable, only bridle #2 was included in the derivation of the analytical stall condition system model.