As we all know, the production of color coating plate has its own industry standards, such as GB/T 12754-2006, JIS 3312, ASTM A755M, EN10169 and other international specifications, in which the film thickness specified in the production of color coating plate is specified. Because it is difficult for the user of color coating plate to determine the film thickness value, in the actual production, many manufacturers deviation the lower limit of the specified value production.Although temporarily can fool the user, however such caitu most difficult to endure the test of time, most of the product in the use of 3-4 years appear fall off paint pulverization, substrate rusty phenomenon occurs, users complain about the quality of producers, asking change color plate or to brush paint, gave the two sides have brought huge economic losses.How to ensure the thickness of the coating film in the production process is a difficult problem which has long puzzled the production workers of the coating line.Here’s a method:

Film thickness is controlled by calculating paint consumption per square meter.Were mostly private factory using this method, the method principle is through the coating weight of the consumption per minute, to calculate the consumption of each square of the coating weight, to calculate the dry film thickness of the product, the specific calculation formula is the coating weightcost per minute /(linear velocity * product width), and according to the paint coating rate, can be calculated 1 μ of dry film thickness is equivalent to how many grams of coating formula.

The above methods have well controlled the cost of color coating production, avoided the occurrence of excessive quality, and provided strong support for the company’s products in the market competition.

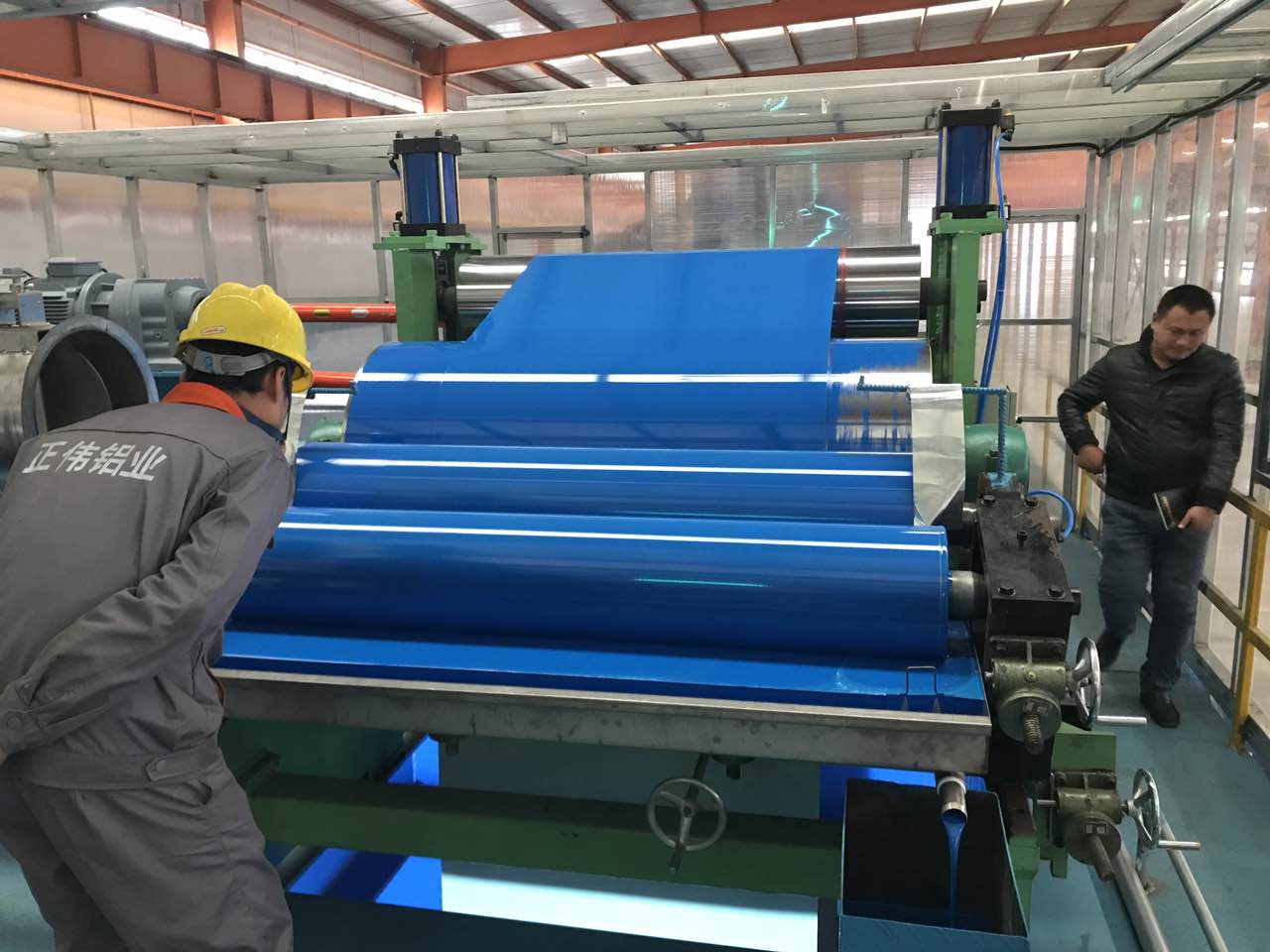

color-coating-line